Our Offerings...

GAG specializes in providing tailor made solutions to the coating requirements of the costumer. The solutions offered by us are proposed only after detail study of the final requirement of the product, which enables us to have absolute clarity of the project in the beginning enabling us to deliver the final product within shortest possible time.

We have executed many projects on turnkey basis in record time for various applications in automobile industries, home appliances industries etc.

- PRE-TREATMENT LINES

- COMPONENT CLEANING MACHINES

- BLASTING Machines

- PAINT BOOTH

- POWDER COATING BOOTH

- OVEN

Pre-Treatment Lines

GAG advanced multistage pre-treatment systems are perfectly suited for both batch and continuous operation. These perform a thorough cleaning of all metal parts to be processed, and provide superior corrosion protection. Reducing effluent load uses cascaded ranges for water conservation, there. Clean bath and bath life is achieved by incorporating continuous oil separation and phosphate sludge separation system. Flexible nozzles ensure easy adjustment of spray direction and air pocket direction. Quick release pipe coupling and nozzles aid easy maintenance.

Spray Pre-Treatment Line

This method of pre-treatment employs the use of an electrical motor to power a pump providing pressurized solution through a heating coil to a hose and hand held wand assembly.

The heat is providing by oil or gas fired burner to a heating coil that is part of this stand-alone system.

Advantages: Can be used for large and bulk components.

Disadvantages: Skilled labors required for troubleshooting.

Dip Pre-Treatment Line

This process is dipped process, which employs one or more tanks That holds solution in which the parts are batched or process dipped continuously via overhead conveyor. This is basically preferred for batch process.

Advantages: Simple to maintain, low capital cost, prolonged chemical contact time is possible complete contact with chemical solution and more flexible chemistry can be used.

Disadvantages: Suits for batch process only.

Re-circulating Spray Process

This the most preferred pretreatment process used in the industry as it has better efficiency. This process reduces the waste management systems.

Advantages: High efficiency levels of cleaning and conversion possible. Re-circulation keeps the part in contact with fresh solution. Process time can be shortened energy saving is possible.

Disadvantages: High capital and maintenance cost. Trouble shooting techniques requires expertise.

Component Cleaning Machines

GAG caters to parts cleaning machines and is an entity managed by highly experienced professionals with a wide experience in the field of parts cleaning and surface treatment technology. We manufacture Industrial parts washing machines, Parts cleaners, Component cleaning machines, Semi-automatic & automatic industrial washing machines, Batch type washing machines, Ultrasonic cleaning machines.

At GAG we value our customers, and endeavor to offer the best solutions backed by responsive and efficient service. We contribute by being most innovative, competitive and offer cost effective solutions to enhance your quality output. This is all supported by range of products, services and offering total solutions in parts cleaning and surface treatment equipment, supported by standard, as well custom-built products and services to engineering, automobile and allied industries.

Our equipment’s are designed, based on understanding the components and customers cleaning requirement which helps us in offering solution for their cleaning needs with right selection of chemicals and assured performance at minimum cost.

Rotary Table Type

Cabinet Type

Conveyorized Type

Rotary Flood

Blasting Booth

Manufacturer, Exporter and Supplier an exemplary range of Portable Abrasive Blasting Machine, Blasting Cabinet, Industrial Dust Collectors and Consumable Spare Parts. Under this range, we offer Air Operated Abrasive Blasting Machine, Wood Working Machinery Dust Extraction unit, Abrasive Blasting Media and various others. These products are designed by our professionals with high-grade components and other basic raw material. All these products are highly demanded in the market for their enhanced productivity, high efficiency, low maintenance, least running cost, optimum performance and convenient installation. Owing to these features, offered products are highly demanded in various industries. Besides, we are providing all these products to the clients at highly affordable prices.

Tumble Blast

Swing Table Shot Blasting

Multi Table Shot Blasting

Shot Blasting for Aluminum Casting

Spinner Hanger Type Shot Blasting

Door Hook Type Shot Blasting

Continues Monorail Shot Blasting

Roller Conveyor Shot Blasting

Pipe Shot Blasting

Plate Shot Blasting

Strip Shot Blast

Stones and Ceramic Blasting

Cylinder Shot Blasting

Coil & Wire Shot Blast

Bar Shot Blasting

Wire Rod Shot Blasting

Billet Shot Blasting

Wire Mesh Belt Shot Blasting

Shot Peening

Roll Etching

Railway Shot Blasting

Steel Mill Equipment

Pressure and Suction Blast Hand Cabinets

Paver Block Shot Blasting

Sand Blast Pot

Shot Blast Wheels

Dust Collectors

Abrasives

Spare Parts & Accessories

ReBar Epoxy Coating

ReBar / TMT Shot Blasting

Aluminum Profile Shot / Sand Blasting

Scaffolding Cleaning Shot Blasting

Paint Booth

Various range of industrial paint booths is based on a modular concept. This concept enables each booth to be customized to suit any specific requirement. The size of the Booth is determined by the size, shape, production of the components, etc… to be coated. Booths are designed, engineered and built to comply with INTERNATIONAL STANDARDS whether the surface is WOOD, PLASTIC or METAL. We can create paint booths that exactly meet your requirements irrespective of object, size and shape. Side draft or down draft booths, pressurized and non-pressurized booths, water wash & non-water wash booths, painting-cum-baking facilities for refinishing of cars can be created.

Most advanced booths with 99.9% over spray PAINT COLLECTION EFFICIENCY with VOC emissions well within permissible world standards are offered

Water Wash

Spray Booth

Dry Filter

Spray Booth

Semi Dry Filter

Industrial Spray Booth

Down Draft

Industrial Spray Booth

Automotive

Spray Booth

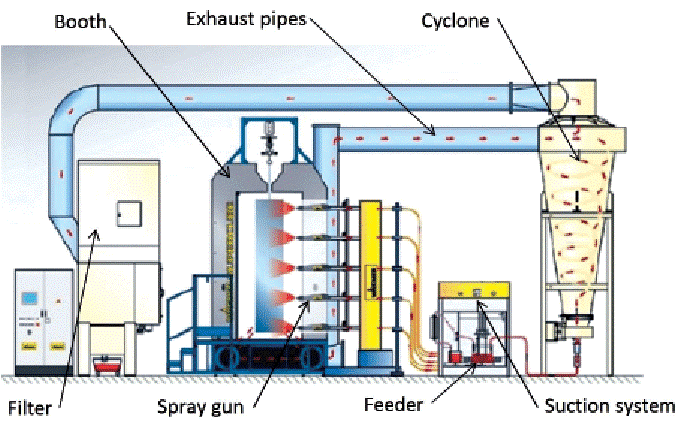

Powder Coating Booth

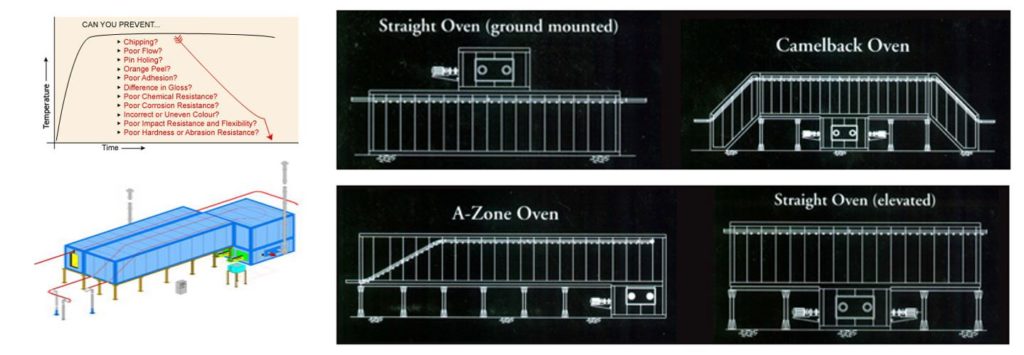

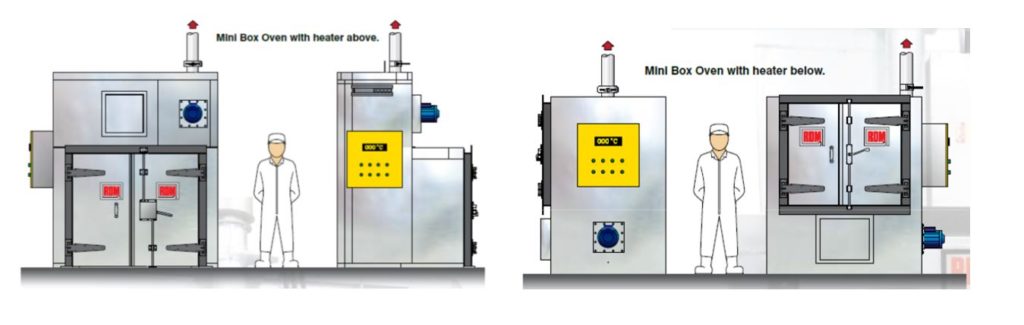

Oven

Ovens are available ‘stand mounted’ or ‘floor mounted’ Mini Box Ovens are shipped, pre-built, pretested and ready to run. All GAG Ovens include a pressurised solvent and fume exhaust system and our triple safety system as standard.

Standard Temperature Range up to 250°C. We offer versions up to 500°C.